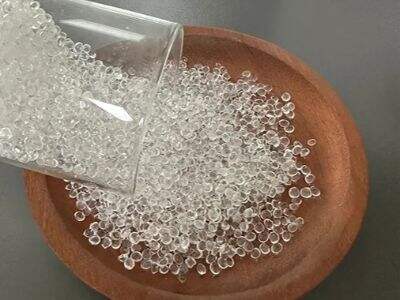

Plastic is of many types which are use by people to produce different kind of things but one of the new and trending type is POE plastic particles. POE stands for Polyolefin Elastomers. It is a soft, very stretchy, rubbery type of plastic. What gives POE plastic particles exceptional properties and benefits due to which it is widely used for manufacturing many products? In this article, we will discuss POE plastic particles: what each of them has to convey when utilized for manufacturing, and Why these offers a fantastic granting.

Usage of POE Plastic Particles

POE plastic particles are stretchy, flexible, and strong, which make them very versatile. These particles are very popular, ubiquitous, used in car components, medical devices, and toys. Car producers, for example, use poe plastic particles to create significant parts such as bumpers, dashboards, and door panels. POE plastic is also quite strong, not easily cracking or splitting due to scoring impacts. POE plastic is used in the hospitals to make tubes and other tools that we want to bend and are still strong. These particles are employed as toy and sports equipment to help keep toys strong yet flexible to withstand vigorous play in the toy business.

Why POE Plastic is Beneficial

One of the major advantages of poe plastic resin particles is their durability. They are impact and wear resistant which means they can be used in products that we daily use. They are pretty strong so that they last for a long time without breaking. POE plastic particles also have very good flexibility. This means they can be stretched extremely without breaking or tearing, which is critical for many products that need to able to bend and be flexible.

POE plastic particles are also easy to process for manufacturers. They can be melted and shaped into all kinds of forms. The shifting shape is beneficial for job manufacturing. Fast and easy production ensures that the entire process can be speeded up and made more affordable.

Easing Assembly with POE Plastic Components

POE plastic particles can also help to facilitate and precision in assembly. This is possible thanks to their ability to be melted down easily and shaped into almost any complex shape that is often difficult to produce with other materials. In other words, manufacturers can eliminate excess part requirement, thereby saving considerable auto assembly time. This can make the process of building products faster and simpler as there are less components to assemble. Additionally, due to the flexibility of POE plastic, it can minimize the process of welding or sealing steps that tend to be time-consuming.

The Green Advantages of POE Plastic Particles

One more significant benefit of POE plastic pellets is that are environmental pleasant. This means it is eco-friendly. The recyclable and reusable properties of POE plastic helps in reducing the waste generated during the manufacturing process. If products are designed to have a longer life cycle, we do not need to replace them as frequently. It also cuts waste with less stuff making to the landfill.

POE plastic parts have unique qualities

There are some unique qualities as a result of poe plastic material particles that make them suitable for wide range of applications. Firstly, they are low-density which makes them light. This means they are lightweight and mobile during the production process. POE plastic also demonstrates a very high level of resistance to chemicals. This is essential since they may be used in challenging industrial settings where they would interact with hostile materials. Importantly, those particles are resistant to UV radiation, allowing them to be used in products exposed to sunlight without degrading.

Overall, POE plastic particles are versatile and green material that offer extensive advantages to manufacturing. They are sturdy, durable and manipulate easily, making them ideal for almost every kind of product. This makes them complex but as a unique properties great for use in manufacturing processes in which efficiency and precision are critical to product quality as well as in extreme conditions. Yican is committed to producing high-quality products made from durable and environmentally friendly POE plastic particles according to the needs of our customers.